Primary Objective: Design and construct a large work surface to be used in the “Arts & Textiles” area of a non-profit maker-space. Budgetary constraints necessitate the use of inexpensive materials.

Secondary Objective: Gain familiarity with Fusion 360 for CAD and CAM and experience with CNC machining, while leveraging parametric design to minimize material waste.

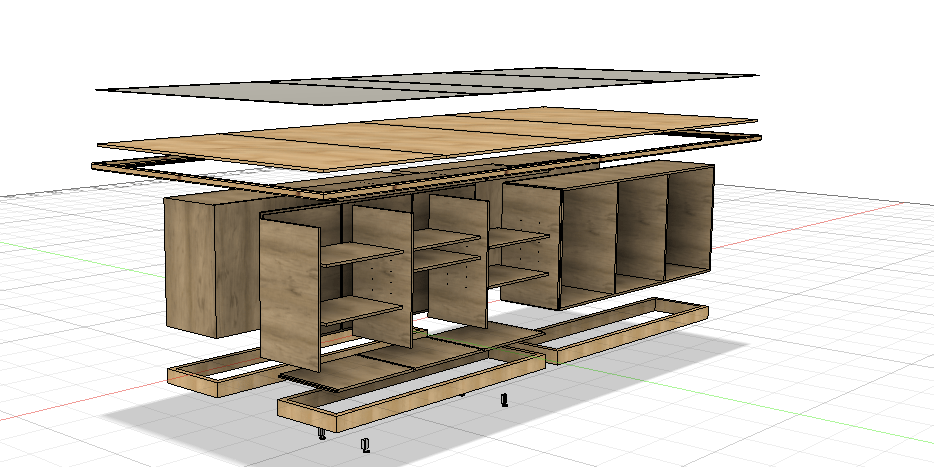

- Specific Goals: A design that is constructible and suitable to the client’s budget. A modular design will increase the future usability of the investment as the space use changes over time.

- Measurable and Achievable Goals:

- 1) Design modular model

- 2) run test cut and

- 3) construct “proof-of-concept” module

- 4) collect materials

- 5) organize volunteer labor into manufacturing blocks

- cutting

- sanding

- staining

- glue-up

- final construction and placement

- trim

- Time-Bound Goals: 4 weeks from start to finish

Method:

- Build a single module

- Qty 2 – 4’x8′ sheets of construction grade plywood material was cut and transported “flat pack” style to my basement as the “proof of concept test”. Total cut-off waste for each module is pictured.

- Glue-up and finish-nail

- Set leveling base

- Attach cabinetry to base

- Construct entire work table

- Cut all 8 sheets of plywood, sending to “sanding team”, then “staining team” and overnight drying

- Transport flat-pack parts to second floor

- Glue-up and finish nail

- Set leveling bases

- Attach cabinents

- Attach Qty 3 4’x6′ sheets of plywood for table sub-base and connect structure

- Add 2′ plywood cut-offs to table end shelving

- Attach 2″x4″ milled trim pieces to table outside

- Apply masonite top for final work surface with double-sided carpet tape

- Masonite is ultra smooth and easily replaced if damaged

Leave a comment